The GIESSER production.

Of knives and men.

From the handle to the blade:

our knife factory in Winnenden works with the utmost precision, every step of the way.

Three factors matter when it comes to producing a high-quality kitchen or butcher knife: the basic materials, the hardening method and the final processing.

What is most important, however, are the people

behind the product. Every day, they operate our

cutting-edge machines and produce more than

8,000 GIESSER knives. The Giesser family consists of 130 motivated employees.

Joseph is one of them. For the past two years, he has been sharpening and testing blades for GIESSER. His work starts at 6 AM. Joseph values the Giesser family as a reliable employer, and he is fully convinced of the products to which his work contributes.

“A knife must be sharp, durable

and comfortable to use.”

“I like the tomato knife best. It‘s nice and small and handy.” He has given one to his wife, who appreciates it just as much and uses it in the kitchen all the time. With a laugh, he adds:

“My wife just loves this knife. And it’s her opinion that counts for me.”

GIESSER produces more than 8,000 knives every day.

Alex and his colleagues check each of them individually.

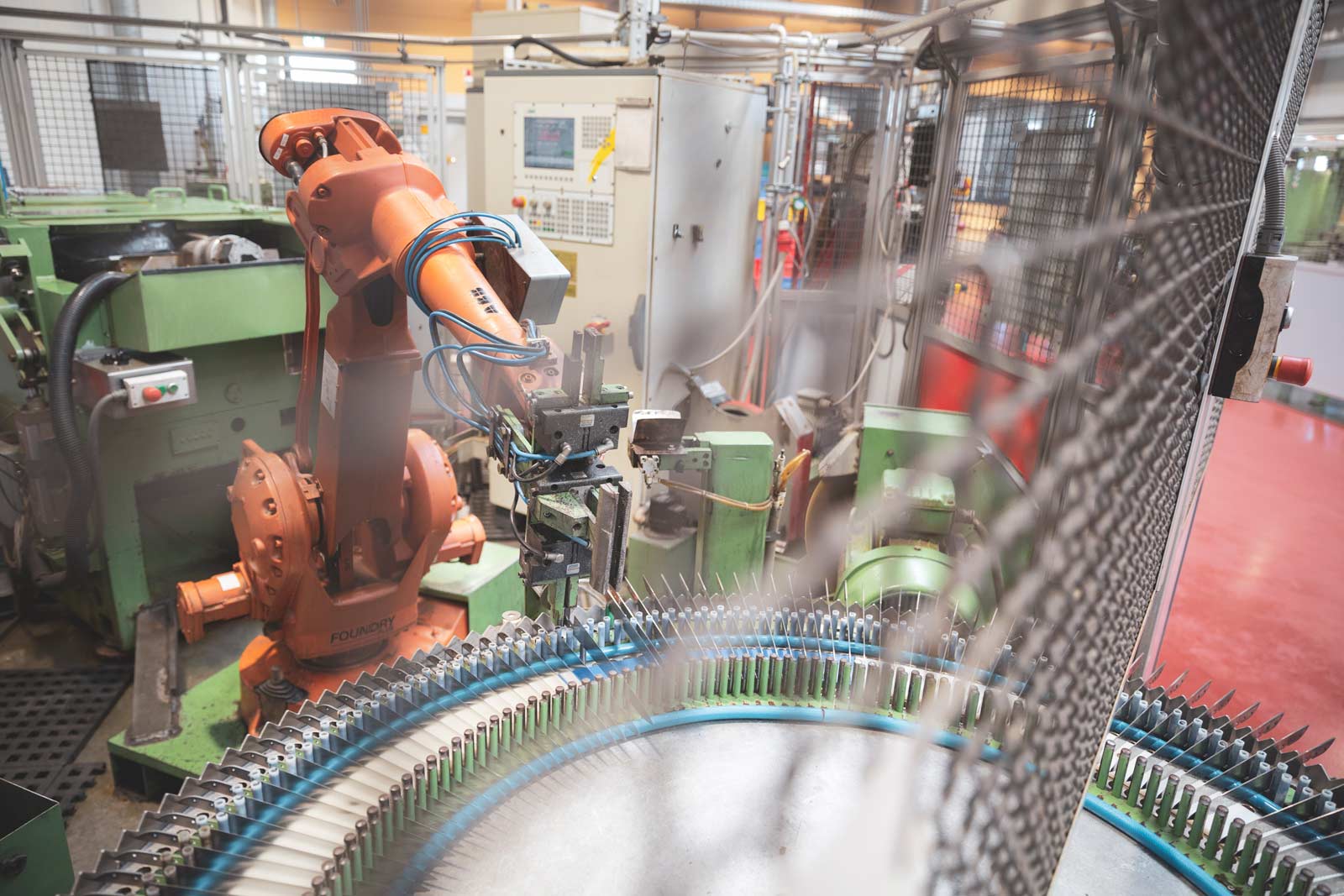

Geselle Pascal hat bereits seine Ausbildung bei GIESSER absolviert, vor drei Jahren wurde er als Schneidwerkzeugmechaniker übernommen. Er hat an den Maschinen seine Berufung gefunden: „Ich arbeite hier an meinen beiden Schleifrobotern. Es ist eine ganz neue Technologie. Damit Messer herzustellen, ist etwas Besonderes, das kann nicht jeder!“

A true technology aficionado, Pascal is excited

about the future of knife production and his own future in the company. Technological progress, the sustainable use of resources and considerate staff management go hand in hand here.

GIESSER apprentices learn the time-honoured art of knife-making

from scratch. It’s an indispensable qualification.

I sure can.”

Domenique at his workbench. He is proud to be learning a traditional trade.

GIESSER is one of Germany‘s top-rated providers of apprenticeships. Our apprentices regularly receive awards in federal state competitions for young tradespeople. That‘s no coincidence: our training concept merges tradition with progress. We teach every step of the traditional art of knife-making in depth. Only after mastering those essential skills do apprentices proceed to the production facilities, which operate state-of-the-art machines and robots today. Domenique, a final-year apprentice cutting-tool mechanic at GIESSER, appreciates the foundation training:

“It is an incredibly exciting profession. I learn a

lot about craftsmanship and get to make my own knives.” Domenique’s favourite item is a pocket knife which he produced during his apprenticeship. After his examination, he will possess a certified wealth of knowledge that qualifys him to operate the production facilities. Technological progress on a traditional foundation.

Service FOR CUSTOMERS

Contact

Johannes Giesser Messerfabrik GmbH

Johannes-Giesser-Straße 1 | 71364 Winnenden

Germany

Telefon: 07195/1808-0

Telefax: 07195/64466

E-Mail: info@giesser.de

Web: www.giesser.de